Manufacturing Plant

Cable Assembly

1.More than 500 well trained employees in this factory

2.16 production lines/3 millions terminations per month

3.Over 200 types of new products designed by Fibercan

4.Products range from FTTX to Data Centre

Precision Molds &Plastic Injection

1.40 sets of plastic injection machines

2.Designed and produced more than 800 sets of molds

3.Mainly for plastic parts like connectors,splice tray ,outlet,wall box etc

4.Capable for own-designed or customized

Optical Cable and Cable Equipment

1.15 professional production lines

2.Different types of cable for indoor and outdoor application

3.Drop cable CPR Cca,CPR Dca,UKCA certified

4.Indoor&outdoor cable equipment,Data cable equipment

5.Interferometer and automatic microscope

Metal Work

1.Advanced Laser Cutting machine and other machines

2.Manufacturing for patch panel,wall box and other metal components

for fiber optic application

Test instruments

1.Plant in Shanghai is a professional and experienced workshop for test instruments.

2.Fibercan designs and provides the testing instruments customized.

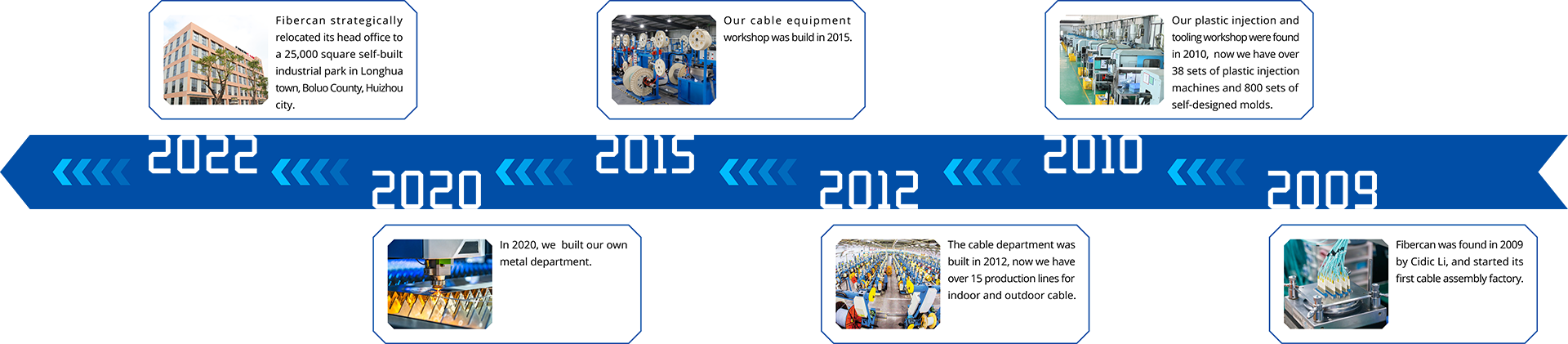

Fibercan History

Development Pillars

◆ Society

The key thought of Fibercan is always what we dedicate for this society,forpeople all over the world.

◆ Customers

We have been offering the best support for every parts to our customersand happy to see their success

because of our support.

◆ Product

The great focus we put on product itself making us being energeticon this market.Good product is the

best answer to people who rely on Fibercan.

◆ Environment

Environment friendly is one of the key points during our manufacturing processes.

◆ Suppliers

We appreciate the great supports from our suppliers and sincerely respect all their efforts during our

development processes.

◆ Employees

Great company is always with great people inside.We care all our employeeswith their health,career,family

and everything in their life.